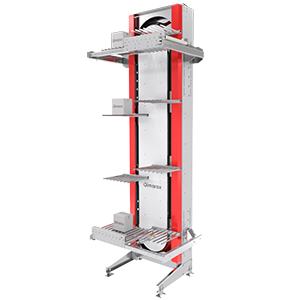

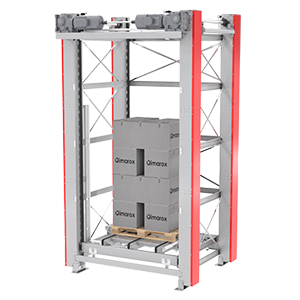

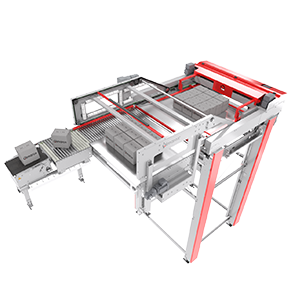

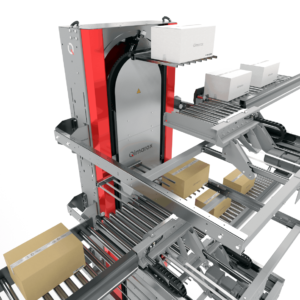

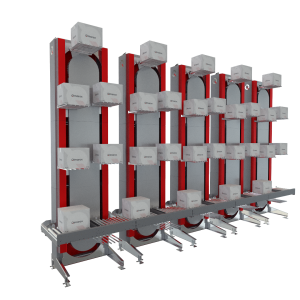

Fraxinus becomes Certified System Partner – Qimarox Palletizing

Fraxinus has been certified as a system partner of Qimarox, a leading supplier of palletizing modules. The collaboration with Qimarox enables Fraxinus to offer its customers the most advanced and efficient palletizing solutions, along with the necessary support.

FRAXINUS WHAT’S IN A NAME?

The name Fraxinus is the Latin word for ‘ash’. As well as a reference to the name of founder Hans Van Essche, it symbolises the tree that we stand for: fraxinus excelsior. Ash is strong but flexible. It has been used for tools since ancient times – you’ll find it in many axe and spade handles.

And it’s a perfect fit for our ethos at Fraxinus: sophisticated, yet sturdy automation systems capable of adapting flexibly to current and future needs.

Fraxinus was established in 2004. From our company base in Roeselare, we design and build systems for a wide variety of sectors across different continents.

WHAT WE DO

Fraxinus designs and builds custom systems for all kinds of production environments and sectors. The overarching goal is always the same: to make logistics flows and production processes as efficient as possible in an optimised work environment.

AUTOMATION IN PRODUCTION PROCESSES

Are you investigating how you can put your production teams to work ‘smarter’ and systematically reduce errors to a bare minimum? Or perhaps you’re looking into speeding up your production process in order to increase capacity? Here at Fraxinus, we design and build custom systems with just one overarching objective: to get more profit from your production process.

PICKING, PACKING AND VALUE ADDED LOGISTICS

You’re also in the right place with Fraxinus if you have a complex packaging and logistics project! Our engineers and specialist technicians build robot tracks, packing lines and internal transport systems to make the logistics flow in the production process as efficient as possible.

THE WAY WE DO THINGS

In every project we’re involved with, we want you to experience the typical Fraxinus style: we strive constantly for added value, while keeping the process as simple as possible. We leave nothing to chance, and we believe in short communication paths. In other words: we take a no-nonsense approach to developing a system that will exceed expectations.

1 | THE TASK

During the first stage, we sit down together to outline the project. What needs to happen? Where will the challenges lie? Preparation is key – we can’t afford to be slack at this stage! If necessary, we’ll underpin the exploration with a preliminary study using 3D modelling.

2 | OUR PROPOSAL

We use all the information we’ve gathered to generate a proposal, which we then present to you. Together, we’ll sit down to develop it into a concrete plan with a budget. At this stage, we’ll also finalise the delivery schedule and any other agreements.

3 | ENGINEERING

All our systems are developed from detailed 3D drawings that we’ll discuss with you at regular intervals. Sometimes, new ideas emerge during this phase: it’s no problem at this stage for us to integrate these into the final system.

4 | PRODUCTION

Once the design has been finalised, our team of experts gets started with production of the components. We have an extensive range of advanced machinery for exactly this purpose. The system is assembled in our own workshop, where we test the control systems and programming down to the last detail – that way, we can be sure that the final installation on your site will go smoothly.

5 | ON-SITE INSTALLATION

Once everything has been thoroughly tested, our installation team will assemble the system at your production site and make sure everything is correctly cabled ready for a smooth launch.

6 | POST-LAUNCH FOLLOW-UP

Once your system is up and running, we’ll still stay on board to make sure that everything is working perfectly. If you have questions or issues once your system is installed, your assigned contact person will always be happy to help.

CONTACT DETAILS FRAXINUS

Wijnendalestraat 162

8800 Roeselare

Belgium

T: +32 51 30 78 53

BE 0459.423.672

E: info@fraxinus.be